Last updated on

In the realm of fluid management, finding the ideal pumping solution can be a daunting task. Whether you’re a seasoned engineer or a novice in the field, the choice of pumps can significantly impact your operations.

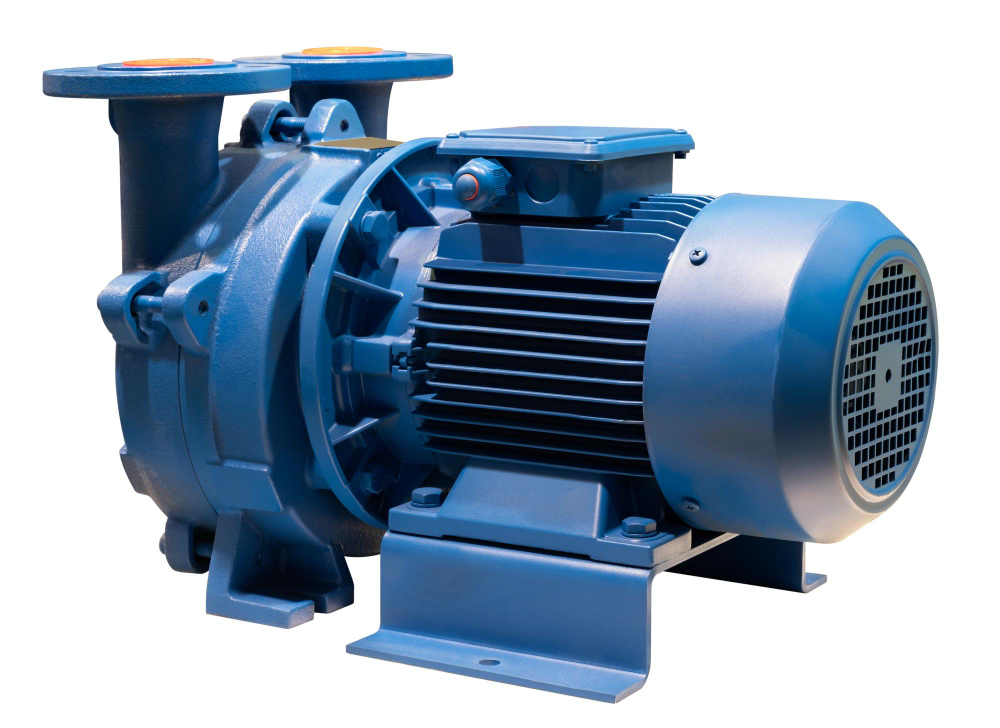

CH&E pumps, renowned for their efficiency and reliability, offer a wide range of options. In this article, we’ll guide you through the five essential steps to help you easily find the perfect CH&E pumps for your specific needs.

Understanding the CH&E Pump Advantage

Before we dive into the steps, let’s explore why CH&E pumps have gained such a solid reputation in the industry. CH&E, which stands for Centrifugal, High-Efficiency, and End-Suction pumps, are known for their top-notch performance. These pumps are designed to handle a variety of fluids, making them versatile for numerous applications.

Now, let’s embark on our journey to finding the ideal CH&E pump.

Define Your Application Requirements

The first and most crucial step is to clearly define your application’s requirements. Understanding the type of fluid you’ll be pumping, the flow rate, pressure, and temperature conditions is essential. Are you dealing with water, chemicals, or abrasive materials? Are you pumping in a high-pressure environment or a low-flow, high-head scenario?

Let’s take an example from real life: Imagine you’re managing a large-scale agricultural irrigation project. In this case, you’ll need a CH&E pump capable of handling a high flow rate to efficiently distribute water across your fields.

Consider Pump Efficiency

Efficiency is paramount when it comes to CH&E pumps. These pumps are designed to minimize energy consumption while delivering reliable performance. Look for pumps that meet or exceed industry standards for efficiency. Energy-efficient pumps not only reduce operational costs but also have a positive impact on the environment.

Imagine you run a wastewater treatment plant. By choosing an energy-efficient CH&E pump, you can significantly cut down on electricity expenses, ensuring both cost savings and sustainability.

Evaluate Pump Materials and Construction

The materials and construction of CH&E pumps play a crucial role in their longevity and performance. Consider factors such as corrosion resistance, durability, and compatibility with the fluid being pumped. Stainless steel, cast iron, and various composite materials are commonly used in CH&E pump construction.

Let’s say you’re in charge of a chemical processing facility. Choosing a CH&E pump constructed from materials resistant to chemical corrosion is imperative to ensure long-term reliability.

Assess Maintenance and Serviceability

Maintenance is an aspect often overlooked until a pump faces issues. To avoid unexpected downtime and costly repairs, opt for CH&E pumps that are easy to maintain and service. Look for features like removable casing for easy access to internal components and replaceable wear parts.

Picture yourself managing a municipal water supply system. In such a critical application, having CH&E pumps that can be swiftly serviced ensures uninterrupted water distribution to the community.

Seek Expert Advice and Perform a Comparative Analysis

While you now understand your requirements better, it’s always wise to seek expert advice. Engaging with a trusted supplier or consulting with engineers experienced in CH&E pumps can provide valuable insights. They can help you perform a comparative analysis of available options, considering factors like initial cost, life-cycle cost, and warranties.

In real-life scenarios, consulting with experts and conducting a comparative analysis can be likened to hiring a professional guide for a challenging mountain expedition. Their experience can save you from potential pitfalls and ensure a successful outcome.

The Takeaway

In conclusion, finding the perfect CH&E pump doesn’t have to be a daunting task. By following these five steps, you can streamline the decision-making process and select the ideal pump for your specific application.

Remember to define your requirements, prioritize efficiency, assess construction materials, consider maintenance, and seek expert advice. By doing so, you’ll be well on your way to ensuring reliable and efficient fluid management.

Recap

Liked this article? Here's what you can read next: