Last updated on

Explore a variety of flooring options for your concrete slab, as we delve into their benefits and installation techniques to help you make the perfect choice.

Concrete slabs are a popular choice for flooring in many homes and buildings. They offer durability, stability, and a sleek modern look.

However, while concrete may be a practical option, it can also be quite uninviting and cold. But fear not! There are plenty of ways to add warmth and style to your concrete slab without breaking the bank.

In this article, we will explore some creative flooring options that will transform your space from drab to fab. Whether you’re renovating an old basement or building a new home from scratch, we’ve got you covered with our budget-friendly ideas that will leave your guests wowed!

Benefits of Concrete Slab Flooring

One of the most significant advantages is its durability. Concrete floors can withstand heavy foot traffic, furniture movement, and even machinery without showing signs of wear and tear.

Another benefit is the low maintenance required to keep concrete floors looking their best. Unlike other types of flooring that require regular cleaning or refinishing, concrete only needs occasional sweeping or mopping to maintain its shine.

Concrete slab flooring provides excellent thermal mass properties which help regulate indoor temperatures by absorbing heat during the day and releasing it at night when needed. This feature makes them an ideal option for homes in hot climates where air conditioning costs can be high.

Types of Concrete Slab Finishes

One popular choice is polished concrete, which involves grinding and polishing the surface until it’s smooth and shiny. This finish is not only aesthetically pleasing but also durable and easy to maintain.

Another option is stamped concrete, which mimics the look of natural stone or brick by imprinting patterns onto the surface while still retaining all the benefits that come with a solid slab foundation.

Stained concrete flooring techniques can add color to your floors without covering up their unique texture. Acid stains react chemically with minerals in the cement creating beautiful marbled effects that will last for years.

Epoxy coatings provide an extra layer of protection against wear-and-tear as well as spills making them ideal for garages or industrial spaces where durability matters most.

Overlays and micro-toppings offer endless possibilities when it comes to design choices since they can be customized according to your preferences giving you complete control over how your floor looks like.

Installing Polished Concrete Floors

The process of polishing concrete involves grinding the surface with progressively finer diamond abrasives until it becomes smooth and shiny. This creates an attractive finish that is both durable and easy to maintain.

To install polished concrete floors, you will need to start by preparing the surface of your existing slab. This may involve removing any old coatings or adhesives, repairing cracks or imperfections in the surface, and cleaning thoroughly.

Once your slab is ready for polishing, you can begin by using coarse-grit diamond abrasives on a floor grinder to remove any remaining blemishes from the surface. You will then gradually work through finer grits until you achieve your desired level of shine.

After polishing is complete, it’s important to apply a sealer that will protect against stains and moisture damage while also enhancing the appearance of your new floor. There are many different types of sealers available depending on whether you prefer matte or glossy finishes.

Stamped Concrete Floor Designs

This technique involves pressing patterns or textures into freshly poured concrete to create the look of natural stone, brick, wood planks or even custom designs. Stamped concrete can mimic the appearance of expensive materials at a fraction of their cost while providing durability and low maintenance.

The process starts with preparing the surface by cleaning it thoroughly and applying a base color that will serve as an accent to your chosen pattern. Then comes stamping – using specialized tools that press down on wet cement before it dries completely – creating texture imprints in various shapes such as squares, circles or diamonds.

Afterward comes coloring- adding pigments to enhance depth and dimensionality- followed by sealing which protects against stains from spills like oil-based liquids while also enhancing its shine.

Stained Concrete Flooring Techniques

Staining can transform a dull, gray surface into a vibrant work of art. There are two types of stains: acid-based and water-based.

Acid stains react chemically with the concrete, creating unique patterns that cannot be replicated by any other method. Water-based stains penetrate the surface more evenly but do not produce as dramatic an effect as acid-stains.

Before applying any stain, it’s essential to prepare your floor properly by cleaning it thoroughly and repairing any cracks or imperfections in the surface. Once you’ve prepped your floor, you can begin applying your chosen stain using either a sprayer or roller brush.

The beauty of stained concrete floors lies in their versatility; they come in various colors ranging from earthy browns to vivid blues and greens that will complement almost every decor style imaginable! Whether you’re going for an industrial look or something more rustic-chic, stained concrete flooring techniques offer endless possibilities for customization at an affordable price point.

Epoxy Coatings for Concrete Floors

Epoxy is a two-part coating that consists of resin and hardener. When mixed together, they create a chemical reaction that forms an incredibly strong bond with the concrete surface.

One of the main benefits of using epoxy coatings is their resistance to stains, chemicals, abrasions, and impact damage. They are also available in various colors and finishes such as metallic or glossy which can add an aesthetic appeal to your space.

Installing epoxy coatings on concrete floors requires proper preparation such as cleaning thoroughly before application. The process involves applying multiple layers with drying time between each coat until achieving desired thickness.

Overlays and Micro-toppings

These materials can be applied directly over the existing surface, creating an entirely new look without having to remove or replace the old floor. Overlays and micro-toppings come in various colors, textures, and patterns that allow you to customize your floors according to your taste.

Micro-toppings are thin layers of cement-based material that can be applied as little as 20 mils thick. They create a smooth finish with subtle variations in color and texture for an elegant look.

Micro-topping is ideal for covering up minor imperfections on concrete slabs such as small cracks or stains.

On the other hand, overlays are thicker than micro toppings (ranging from 1/8 inch -2 inches) which makes them perfect for hiding more significant flaws like uneven surfaces or deep cracks on concrete slabs. They also offer greater design flexibility since they can mimic natural stone finishes like slate or flagstone while providing durability similar to traditional polished concrete floors.

Both overlays and micro toppings require proper preparation before application; this includes cleaning the surface thoroughly by removing any dirt, grease stains followed by etching it with acid solution so that it bonds well with overlay/micro topping material.

Concrete Floor Paint Options

Concrete floor paint comes in a variety of colors and finishes that can mimic the look of natural stone or tile. It’s also a great option for covering up stains or imperfections on old concrete floors.

Before you start painting, make sure the surface is clean and free from any debris or oil stains. You may need to use a degreaser or etching solution to prepare the surface properly.

When it comes to choosing paint for your concrete floor, there are two main types: epoxy-based paints and latex-based paints. Epoxy-based paints are more durable but require more preparation work before application as they need an acid-etched surface for proper adhesion; whereas latex-based paints are easier to apply but less durable than epoxy ones.

Once you’ve chosen your preferred type of paint, consider adding some decorative elements such as stencils or patterns using painter’s tape before applying multiple coats with rollers until achieving desired coverage.

Engineered Hardwood On Concrete Slab

Engineered wood is made up of layers of real wood veneer glued together to create a stable and durable product. This type of flooring can be installed directly onto your concrete slab using either glue or floating installation methods.

One advantage to installing engineered hardwood over traditional solid wood is its resistance to moisture damage. The multiple layers in this type of flooring make it less susceptible to warping or cupping due to changes in humidity levels, which can often occur with solid wood floors.

Another benefit is that engineered hardwood comes in a wide variety of styles and finishes, allowing you to achieve any look from rustic farmhouse charm all the way through modern elegance.

When installing an engineered floor on top your concrete slab, it’s important first ensure that there are no moisture issues present by performing proper testing before installation begins. If opting for glue-down method professional help might be necessary as some adhesives require specific application techniques.

Laminate Flooring Over Concrete

It’s durable, low-maintenance, and comes in a variety of styles that mimic the look of hardwood or tile. Laminate floors are also suitable for installation over concrete slabs with some preparation.

Before installing laminate on your concrete slab floor, ensure that it’s level and free from any cracks or moisture issues. You can use self-leveling compounds to even out minor imperfections in the surface.

Next, lay down a vapor barrier to prevent moisture from seeping up through the concrete into your new floor. This step is crucial as excess moisture can cause warping or buckling of your laminate planks.

Once you’ve prepared the surface adequately, install an underlayment pad to provide cushioning and sound insulation between the subfloor and laminate planks.

Snap together your laminates according to manufacturer instructions starting at one corner of the room working towards another end until complete coverage is achieved.

Carpeting for Concrete Floors

Not only does it provide insulation against the cold, but it also adds texture and color to your space. Carpet tiles are an excellent choice for concrete floors as they can be easily installed without the need for adhesives or underlayments.

They come in various colors, patterns, and textures that allow you to create unique designs that suit your style.

When choosing carpet tiles for a concrete floor, consider those with low pile heights as they tend not to trap dirt or dust particles like high-pile carpets do. Opt for materials such as nylon or polyester which are durable enough to withstand heavy foot traffic.

Installing carpet on a concrete floor requires some preparation work before laying down the tiles; ensure that any cracks in the surface have been filled up with patching compound before installation begins.

Installing Ceramic Tile On Concrete

They come in a variety of colors, patterns, and sizes that can complement any decor style. Installing ceramic tile on concrete is relatively easy if you have the right tools and follow the correct steps.

Firstly, ensure that your concrete slab is clean, dry, levelled with no cracks or unevenness before starting the installation process. Next up is applying an adhesive layer using a notched trowel over small sections of the floor at once while laying down each tile firmly into place.

Once all tiles are laid out correctly according to your design plan (you may need spacers), allow them time to set overnight before grouting between them with sanded grout mixture applied diagonally across joints using rubber float tool followed by wiping off excess residue from surface after 15-20 minutes drying period.

Finally sealant should be applied over entire tiled area after it has dried completely which will help protect against moisture damage as well as stains from spills or foot traffic making sure you choose one suitable for ceramic tiles on top of concrete surfaces.

Vinyl Flooring Over Concrete Slab

It’s affordable, easy to install, and comes in a variety of styles that mimic the look of hardwood or tile. Vinyl planks are also waterproof, making them an excellent choice for basements or areas prone to moisture.

To install vinyl flooring over your concrete slab, you’ll need first to ensure that the surface is clean and level. Any bumps or cracks should be filled with self-leveling compound before laying down the underlayment.

Once your subfloor is prepped, it’s time to lay down the vinyl planks. You can choose between glue-down or floating installation methods depending on your preference and budget.

Glue-down installation involves applying adhesive directly onto the subfloor before placing each plank in place carefully. Floating installation requires no adhesive but instead relies on interlocking mechanisms between each plank for stability.

Cork and Bamboo Flooring Options

Cork is a natural insulator, making it an excellent choice for those who want to keep their homes warm in the winter and cool in the summer. It’s also soft underfoot, which makes it comfortable to walk on for extended periods.

Bamboo is another sustainable option that has gained popularity over recent years due to its durability and unique appearance. It’s available in various colors, patterns, and textures that can add character to any room.

Both cork and bamboo floors come as planks or tiles with interlocking systems designed for easy installation without glue or nails. They’re also low maintenance; regular sweeping or vacuuming will keep them looking great.

One thing you should note when installing cork or bamboo flooring over a concrete slab is moisture control since both materials are susceptible to water damage if exposed excessively.

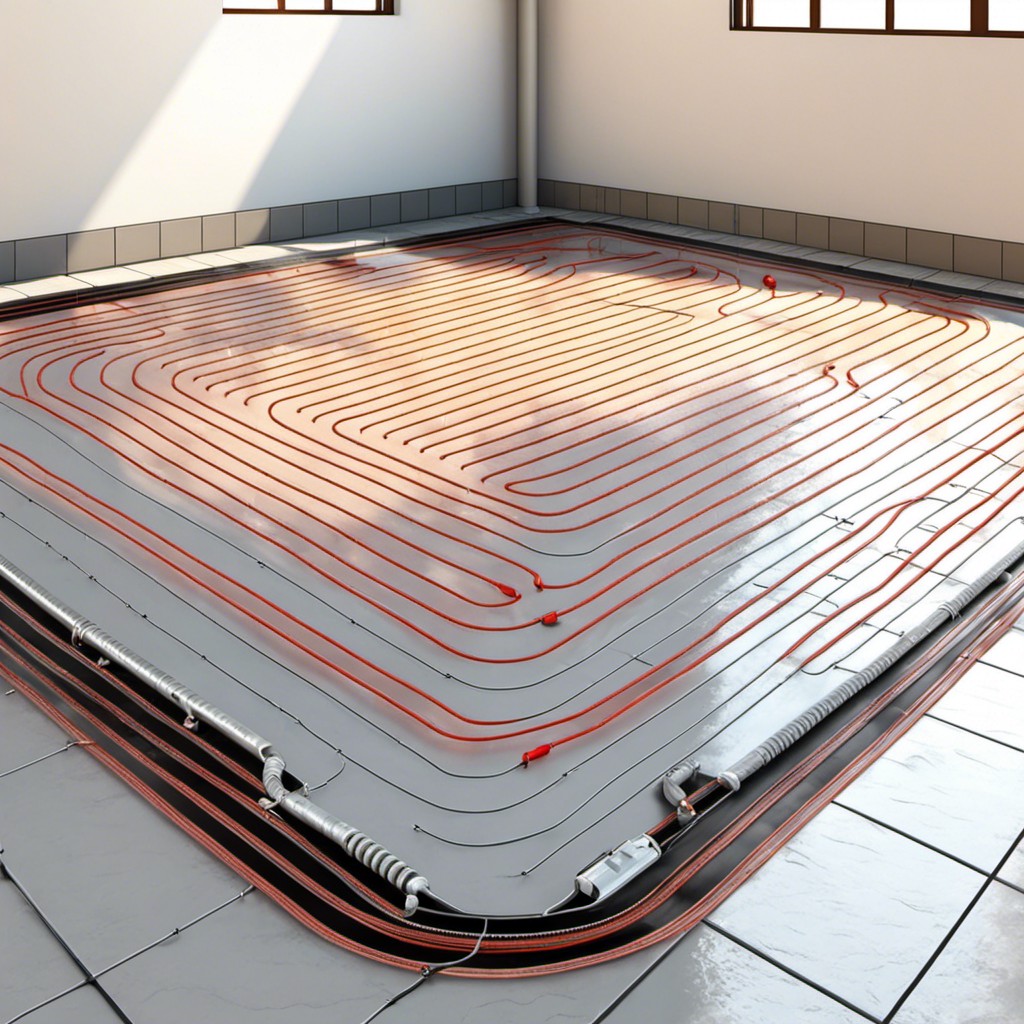

Radiant Floor Heating Systems

These systems work by circulating hot water or electric coils beneath the surface of your floors, providing even heat throughout the room. Radiant floor heating is not only energy-efficient but also eliminates the need for bulky radiators or vents that can take up valuable space in your home.

There are two types of radiant floor heating: hydronic and electric. Hydronic systems use hot water that circulates through pipes installed under the concrete slab while electric systems use cables or mats with built-in wires that generate heat when electricity flows through them.

While installing a radiant floor system may be more expensive than other flooring options, it’s worth considering if you live in colder climates where winters can be harsh. Not only will it keep your feet warm on chilly mornings but also increase overall comfort levels in any room.

There are many ways to transform a cold and uninviting concrete slab into something beautiful and cozy without breaking the bank.

Acoustic Performance of Concrete Floors

The hard surface of concrete reflects sound waves, which can create an echoey and unpleasant environment. However, there are ways to improve the acoustic performance of your concrete slab flooring.

One option is to install a sound-absorbing underlayment beneath your chosen flooring material. This will help reduce noise transmission between floors by absorbing some of the impact from foot traffic or other sources.

Another solution is to add area rugs or carpeting on top of the concrete floor. These soft surfaces absorb sound waves and provide a cozy feel while reducing noise levels in your space.

If you’re looking for a more permanent solution that doesn’t involve covering up your beautiful concrete floor, consider adding acoustic panels or ceiling baffles to absorb excess noise in the room.

Insulating Concrete Floor Surfaces

Insulating your concrete floor surface is an excellent way to keep your feet warm and reduce energy costs. There are several ways to insulate a concrete slab, including installing insulation boards or using spray foam insulation.

One of the most popular methods for insulating a concrete floor is by laying rigid foam insulation boards directly onto the surface before adding any flooring material. These boards come in different thicknesses and R-values (a measure of thermal resistance), so you can choose one that suits your needs best.

Another option is using spray foam insulation, which creates an air-tight seal around pipes or other obstacles that may be present in the slab’s structure. This method provides better coverage than traditional batts or rolls of fiberglass insulation since it fills all gaps between joists and studs.

Regardless of which method you choose, make sure that there are no air leaks around doors or windows as they will compromise any efforts made towards insulating your space effectively.

Moisture Control for Concrete Floors

Excess moisture can lead to mold and mildew growth, which not only damages the flooring but also poses health risks for occupants. To prevent this from happening, it’s essential to take measures that will keep your concrete slab dry.

One way to control moisture is by installing a vapor barrier beneath the flooring material. This barrier prevents water vapor from seeping through the slab and into your home or building.

Another option is using sealers on top of the concrete surface that repels water and keeps it from penetrating.

It’s also important to ensure proper drainage around your property so that rainwater doesn’t accumulate near or under your foundation, causing dampness in the basement or crawl space below.

Maintenance, Repairing, and Restoring Concrete Floors

However, like any other flooring material, they require some upkeep to keep them looking their best. Regular cleaning is essential to prevent dirt buildup that can cause scratches or stains on the surface.

In case of damage such as cracks or chips in the concrete slab floor, it’s important to address them promptly before they worsen over time. Small cracks can be filled with epoxy filler while larger ones may need professional repair services.

Restoration of old concrete floors is also possible with a variety of techniques such as polishing or staining which will give your floor a new lease on life without having to replace it entirely.

By following these simple tips for maintaining and repairing your concrete slab flooring you’ll ensure its longevity while keeping it looking beautiful for years to come!

FAQ

What is the best flooring to put over a concrete slab?

The best flooring options to put over a concrete slab are carpet, engineered hardwood, laminate, or vinyl flooring, as they can last for years with proper maintenance.

Can you put flooring on concrete slab?

Yes, you can put flooring on a concrete slab, as it is compatible with all types of floors, including vinyl and wood.

What is the cheapest way to finish concrete floors?

The cheapest way to finish concrete floors is by using epoxy kits or laying carpet yourself.

What goes between concrete slab and flooring?

Between a concrete slab and flooring, a proper underlayment is used, particularly for wood flooring, and sometimes a plywood underlayment is installed for extra protection after testing for moisture.

What are the most durable flooring options for concrete slabs in high-traffic areas?

The most durable flooring options for concrete slabs in high-traffic areas include epoxy coatings, polished concrete, and rubberized floor coverings.

How do you properly prepare a concrete slab for installing new flooring?

To properly prepare a concrete slab for installing new flooring, ensure the slab is clean, dry, level, and free of any cracks or imperfections.

What are the pros and cons of using epoxy coatings on concrete slab flooring?

Epoxy coatings on concrete slab flooring provide enhanced durability and resistance to chemicals, but require proper surface preparation and can be slippery when wet.

Recap

Liked this article? Here's what you can read next: