Last updated on

Discover the transformation of candy through the freeze drying process because this innovative technique can amplify flavors while introducing a unique, brittle texture.

Key takeaways:

- Freeze-drying intensifies flavors and creates a crunchy texture.

- Freeze dryers remove moisture from candy through sublimation.

- Types of freeze dryers include home, commercial, industrial, and pharmaceutical-grade models.

- Factors to consider when choosing a freeze dryer include scale of production, energy efficiency, and durability.

- Freeze drying candy can be a significant investment with potential long-term benefits.

Overview of Freeze-Drying Candy

Freeze-drying is a unique preservation method that removes moisture from candy by freezing it and then applying a high-pressure vacuum. This process, known as lyophilization, preserves the candy’s structure, intensifies its flavors, and gives it a satisfyingly crunchy texture.

Popular among both confectionery enthusiasts and companies looking to innovate their product lines, freeze-dried candies retain their original shape and size, making for an intriguing and novel treat. The process also extends the shelf life, making it an excellent method for creating durable confectionery goods.

The technique’s growing popularity can be attributed to its ability to create a distinctive snacking experience, tapping into the market’s ever-evolving demand for new and interesting flavors and textures.

Exploring the Freeze-Drying Process

Freeze-drying, also known as lyophilization, transforms candy from a moist and chewy treat into a light, crunchy snack with a longer shelf life. The process begins with freezing the candy to lock in its shape and flavor profiles. Next, the frozen treats are placed under a vacuum, where low heat is applied. This allows the ice to sublimate, directly shifting from solid to gas, bypassing the liquid phase. As a result, moisture is removed without compromising the candy’s structure or taste.

The keys to this preservation technique lie in maintaining low temperatures to prevent melting and exercising precise control during sublimation to ensure complete dehydration. By doing so, candy retains its original shape and size, while acquiring a unique melt-in-your-mouth texture. This process is not only a novel culinary twist but also enhances the candy’s longevity, making it a stable product for storage and transport.

Essential Equipment for Freeze-Drying Candy

The core apparatus needed to transform traditional sweets into freeze-dried delights is the freeze dryer itself. This machine operates by placing the candy under vacuum, removing moisture through sublimation, and preserving the candy’s structure and flavor.

When picking a freeze dryer, consider capacity—single-tray units suit home use, while multiple-tray models cater to commercial operations. You’ll also need airtight storage containers to maintain the crisp texture post-freeze-drying. Protective gear, such as gloves and face masks, ensures safety when handling the machine and frozen products.

For precise operation, a reliable power source and potentially a backup generator are prudent investments, protecting against unexpected outages that could compromise a batch. Lastly, hygienic stainless steel tables provide a sanitary space for preparation and packaging.

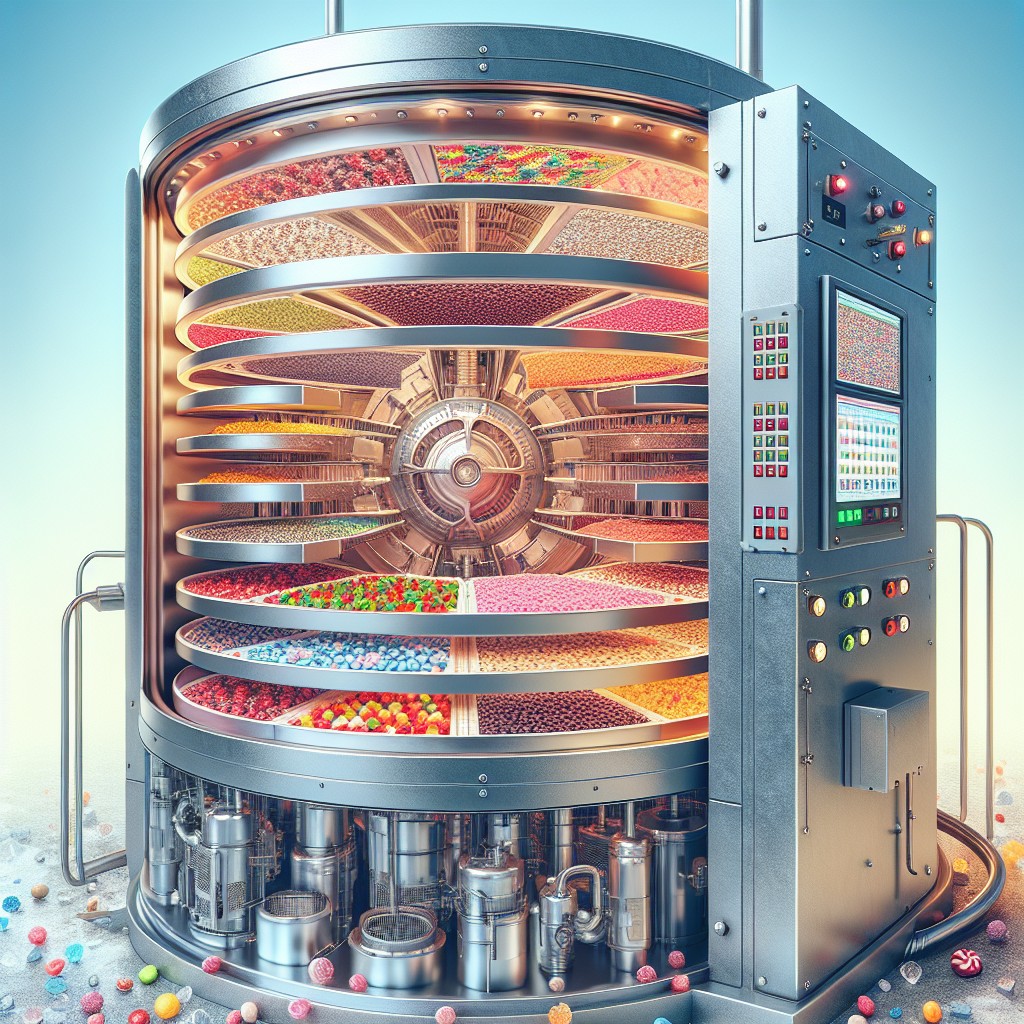

Types of Machines Used for Freeze-Drying Candy

When pursuing the art of freeze-drying candy, a range of machines is at your disposal, each bringing a distinct set of features and capacities tailored to various scales of production.

Home Freeze Dryers: Ideal for small-scale operations or personal use. These compact units fit conveniently on a countertop and are straightforward to operate. They suit anyone looking to experiment with different candy types without the need for industrial output.

Commercial Benchtop Freeze Dryers: A step above home models, these are designed for small businesses or culinary professionals. They offer a larger capacity and advanced features while still being relatively space-efficient.

Industrial Freeze Dryers: For large-scale candy production, these heavy-duty machines provide extensive capacity and are engineered for continuous, rigorous use. They often come with customizable settings to fine-tune the freeze-drying process for optimal results.

Pharmaceutical-grade Freeze Dryers: Although not traditionally used for food, these machines offer the highest precision and control, which some high-end culinary professionals might utilize for creating consistent, premium-quality freeze-dried candies.

Each machine type is engineered with specific technologies to protect the delicate sugar structures within candy, ensuring that texture, flavor, and appearance are preserved post freeze-drying. Vacuum technology and precise temperature controls are integral to all machines, allowing for the sublimation process to occur efficiently and uniformly. When selecting a machine, consider output needs, available space, and budget constraints to identify the one that aligns best with your objectives.

Factors Influencing the Choice of a Freeze Dryer

Selecting the most suitable freeze dryer requires careful consideration of various elements to ensure efficiency and quality in candy production. First, the scale of your operation dictates the size of the machine needed; small batch artisans might opt for a benchtop model, whereas commercial producers require larger, industrial-grade units.

Additionally, the specific types of candy to be freeze-dried can influence the choice of freeze dryer due to differing moisture contents and sensitivities.

Energy efficiency is another crucial factor. Units with better insulation and more effective vacuum systems consume less power, which translates to long-term cost savings. The user interface should not be overlooked; a machine with clear controls and programmable settings streamlines the freeze-drying process and minimizes user error.

Durability is paramount, as higher-quality materials imply less frequent maintenance and replacements. Lastly, some freeze dryers offer advanced features such as automatic defrost cycles and remote monitoring capabilities, which may be desirable based on your production needs and preference for convenience.

Cost Implications of Freeze-Drying Candy

Investing in a freeze dryer for candy production entails significant upfront expenses. The initial cost ranges depending on size and capacity, starting from a few thousand dollars for smaller units to tens of thousands for commercial-grade machines. It is crucial to consider the long-term benefits, such as the ability to offer a unique product line and potentially higher profit margins on freeze-dried candies.

Operational costs also play a role in the overall financial picture. Electricity consumption can be considerable since freeze dryers must maintain low temperatures and a vacuum for extended periods. Additionally, regular maintenance is required to ensure optimal performance, which may include replacing filters, vacuum pump oil, and servicing components subject to wear.

To offset the costs, calculating the potential increase in revenue from offering freeze-dried candies is essential. These treats often command higher prices in the market due to their novelty and extended shelf life. Bulk purchasing ingredients and packaging materials can contribute to cost savings, while efficient production scheduling maximizes machine usage.

Overall, it’s a balance of initial investment, ongoing expenses, and potential profit increases when incorporating freeze-drying into a candy-making venture.

Analysis of Investment: Freeze Dryer Expense Vs. Return

When considering the acquisition of a freeze dryer for candy production, it’s crucial to weigh the initial outlay against potential gains. The expense includes not just the purchase price but also operation costs such as electricity and maintenance. The return on investment hinges on factors like product pricing, market demand, and sales volume.

- Break-even Point: Calculate when the machine will pay for itself. This is achieved when the cumulative profit from sales exceeds the combined costs of purchasing and running the freeze dryer.

- Product Profit Margins: High-quality freeze-dried candies can command premium prices. Determine your profit margins by subtracting the cost of production from the sales price.

- Market Trends: Analyze market demand. Specialty and novelty food items, such as freeze-dried candies, are gaining popularity and can open up lucrative market niches.

- Operational Efficiency: Optimize the drying cycle and batch size. Maximize the capacity of your machine to increase output without compromising product quality.

- Longevity and Durability: Invest in a machine that is known for durability. A robust freeze dryer may have a higher upfront cost but can lead to lower maintenance expenses over time, positively impacting your return.

- Scalability: Should demand increase, consider whether the current machine will meet production needs or if an additional investment will be necessary to scale up operations.

Making an informed decision requires a clear understanding of both the costs involved and the potential revenue from selling freeze-dried candy. A strategic approach to this investment can help ensure its profitability and sustainability within the marketplace.

Maintenance and Repairs of Freeze Dryers

Regular maintenance ensures longevity and optimal performance for your freeze dryer. Here’s what you need to keep in mind:

1. Keep It Clean: After each batch, thoroughly clean the chamber, trays, and gaskets to prevent buildup and contamination.

2. Check Vacuum Levels: Inspect and test the vacuum pump regularly, as a strong vacuum is crucial for proper freeze-drying.

3. Replace Filters: Vacuum pump oil filters should be checked and replaced periodically to maintain efficacy and protect the pump.

4. Monitor Seals and Gaskets: Inspect door seals and gaskets for wear and tear to maintain an airtight seal during the freeze-drying process.

5. Software Updates: If your machine is digitally controlled, keep its software updated to ensure the most efficient operation.

6. Schedule Professional Servicing: Even with diligent maintenance, have your machine inspected by a professional annually to address any hidden issues.

7. Stay Alert for Noises: Unusual sounds can be the first sign of a part needing attention. Don’t ignore them.

By adhering to these points, you can avoid costly repairs and downtime, ensuring a continuous and efficient candy freeze-drying process.

Cost-Effectiveness for Business Operations

Evaluating the cost-effectiveness of a freeze dryer for business operations necessitates a thorough review. First, consider the initial investment against long-term profits. A hefty upfront cost might be justified by the increased shelf-life and uniqueness of freeze-dried candies, translating into higher pricing power and market demand.

Secondly, analyze the operating costs, including electricity, maintenance, and labor. Freeze dryers can consume significant energy, but opting for energy-efficient models can curtail expenses.

Moreover, a business should gauge production scalability. A machine that helps you scale up operations smoothly without incurring prohibitive incremental costs ensures sustained profitability as demand grows.

Last**l**y, don’t overlook the potential for product loss reduction. Traditional candy storage methods may lead to spoilage, while freeze-dried candies have minimized waste due to their extended shelf life, contributing to a healthier bottom line.

It’s crucial for businesses to break down these factors to ensure informed decision-making that aligns with their financial goals and market positioning.

Saving Strategies On Freeze Dryer Purchases

To optimize your expenditure when investing in a freeze dryer, consider the following cost-saving strategies:

– Buy Refurbished Equipment: Purchasing a certified refurbished freeze dryer can significantly lower the initial investment while still providing a reliable piece of machinery. – Consider a Shared Purchase: Teaming up with another business or a group of individuals interested in freeze-dried candy can diminish individual costs. – Seek Out Financing Options: Some manufacturers offer financing plans that allow for a lower upfront cost and manageable payments over time. – Watch for Promotions and Discounts: Vendors may provide seasonal deals or discounts for first-time buyers. Signing up for newsletters and alerts can keep you informed. – Look for Educational Discounts: If you’re involved with an educational institution or a start-up incubator, you might be eligible for special pricing. – Utilize Tax Deductions: Consult with a tax professional to explore potential deductions for business equipment purchases that could offset the overall cost.By employing these techniques, you can make a more economical entry into the world of freeze-dried sweets.

Alternatives to Freeze Drying Candy

If a freeze dryer isn’t accessible or within budget, consider these methods to achieve similarly unique textures and flavors in candy:

Dehydration: Using a food dehydrator can create a chewier, denser product than the crispness of freeze-dried candy. This process involves low heat and airflow to remove moisture.

Oven-Drying: Slower than a dehydrator, oven-drying at the lowest setting with the door slightly ajar can also remove moisture from candy, although results may vary and the texture might be less consistent.

Air-Drying: Simply leaving candy exposed to air at room temperature works well for certain types, such as gummy candies, to enhance chewiness.

Sugar Crystal Growth: Candies left to crystallize, such as rock candy, rely on a different science of evaporation and sugar structure formation. This can create appealing textures without special equipment.

Each alternative offers a distinctive outcome that could attract customers looking for an unusual treat or provide an exciting twist on classic confections. Experimentation could uncover the next big hit in the world of sweet delights.

Comparing Freeze Dryers and Dehydrators for Candy

When choosing between a freeze dryer and a dehydrator for candy production, it’s essential to understand the fundamental differences in how they preserve food.

Freeze dryers work by freezing the candy, then using a vacuum to remove moisture via sublimation, effectively turning ice into vapor without passing through a liquid state. This process retains the shape, flavor, and nutritional value of the candy, resulting in a lightweight and long-lasting product.

Dehydrators, on the other hand, use heat and air flow to evaporate moisture. This method is slower and often results in a product that is tougher and has a more concentrated flavor than its freeze-dried counterpart. While dehydrated candy can still be delicious, it may lose some of its original texture and nutritional content.

Here’s what you should consider:

- Texture and Taste: Freeze-dried candies typically maintain their original shape and structure, providing a crisp texture and preserving taste. Dehydrated candies are chewier and may have a more intense taste due to the concentration of flavors.

- Nutritional Content: Freeze drying better preserves the nutritional content of the original product than dehydrating, which can break down certain heat-sensitive nutrients.

- Shelf Life: Both methods extend shelf life, but freeze-dried candies often last longer due to the near-complete removal of moisture.

- Energy Consumption: Dehydrators usually consume less energy compared to freeze dryers, which may be a consideration for cost and environmental impact.

Each method offers unique benefits, so your choice should align with the specific goals and preferences for your candy-making endeavors.

Evaluating the Need for a Freeze Dryer in Candy Making

Before investing in a freeze dryer for candy creation, consider the following to determine its necessity and potential impact on your production:

1. Product Differentiation: Establish if freeze-drying will offer a unique texture or flavor profile to your candies that can distinguish your product in the market.

2. Scale of Production: Assess your production volume. A freeze dryer is a significant investment that may only be justified for larger-scale operations.

3. Consumer Demand: Research market trends to verify there’s a robust demand for freeze-dried candies. Understand your target audience and their willingness to pay a premium for such products.

4. Shelf Life Extension: Evaluate whether extending the shelf life of your candies via freeze-drying aligns with your business model and distribution methods.

5. Innovation Opportunities: Consider if the freeze-drying process can facilitate the development of new, innovative products, expanding your product line and potentially tapping new markets.

6. Cost-Benefit Analysis: Factor in the cost of equipment, operation, and maintenance against the projected increase in profits from selling freeze-dried candies.

By carefully analyzing these points, you can make an informed decision about the role of freeze drying in your candy-making process.

Community Resources and Support for Freeze-Drying Enthusiasts

Networking with like-minded individuals can be invaluable. Online forums and social media groups offer a platform for exchanging tips, troubleshooting techniques, and the latest advancements.

Local culinary schools or community colleges occasionally host workshops on advanced food preservation methods, including freeze-drying.

Trade shows and food technology expositions are ideal for live demonstrations, allowing hands-on experience with various equipment models.

Manufacturer websites often provide FAQs, user manuals, and sometimes live chat support for more immediate assistance.

Lastly, cooperative extension services in many areas offer resources on food preservation, where you might find guidance specific to freeze-drying.

Exploring Additional Business Ideas Using a Freeze Dryer

Venturing beyond candy, a freeze dryer opens up diverse business opportunities. Pet treats, for example, can be freeze-dried for longer shelf life, retaining nutritional content and flavor that pets love. Additionally, for the health-conscious market, creating freeze-dried fruits and vegetables preserves essential vitamins and offers a portable, snackable option.

Think culinary innovation with freeze-dried herbs and spices, which can intensify flavors in cooking. Chefs and food enthusiasts often seek out these unique ingredients. The arts and crafts scene also offers a niche with freeze-dried flowers, maintaining their beauty and color for arrangements and decorations.

In the realm of emergency preparedness, freeze-dried meals are invaluable. Offering customizable meals that can last for years caters to outdoor adventurers and those looking to stock up for emergencies.

Moreover, incorporating a freeze dryer for creating educational kits—like demonstrating the lyophilization process in schools—could also be an untapped avenue.

Each alternative path not only broadens your product line but also taps into different audiences, maximizing the utility of your freeze-drying equipment.

Practical Tips for Starting a Freeze-Dried Candy Business From Home

Embarking on a home-based freeze-dried candy venture entails more than just the freeze-drying process itself. Here are some essential tips to get you started:

1. Research Compliance Regulations: Investigate local health codes and food safety regulations to ensure your business operates legally.

2. Craft a Unique Brand Identity: Stand out in the market by developing a brand that reflects the unique qualities of your freeze-dried candy products.

3. Select a Niche Market: Focus on specific audiences or candy types to cater to particular tastes and dietary requirements.

4. Set Up A Dedicated Workspace: Allocate a clean, organized space in your home that is strictly for freeze-drying activities and storage.

5. Source Quality Ingredients: Use high-grade, fresh ingredients to ensure the final product is of superior quality and taste.

6. Test and Refine Recipes: Experiment with different candies and flavors to create a consistent product line that appeals to your target market.

7. Create a Marketing Plan: Utilize social media, local markets, and word of mouth to build brand awareness and attract customers.

8. Manage Finances Wisely: Keep meticulous records of all expenditures and income, and make financial decisions that will maximize profits.

Remember, a successful home-based business often starts small and grows through careful planning, consistent quality, and strategic branding.

Recap