Last updated on

In the realm of fluid management, finding the ideal pumping solution can be a daunting task. Whether you’re a seasoned engineer or a novice in the field, the choice of pumps can significantly impact your operations. CH&E, a renowned company for its efficient and reliable diaphragm pumps, offers a wide range of options.

In this article, we’ll guide you through the five essential steps to help you easily find the perfect CH&E diaphragm pump for your specific needs.

Understanding the CH&E Diaphragm Pump Advantage

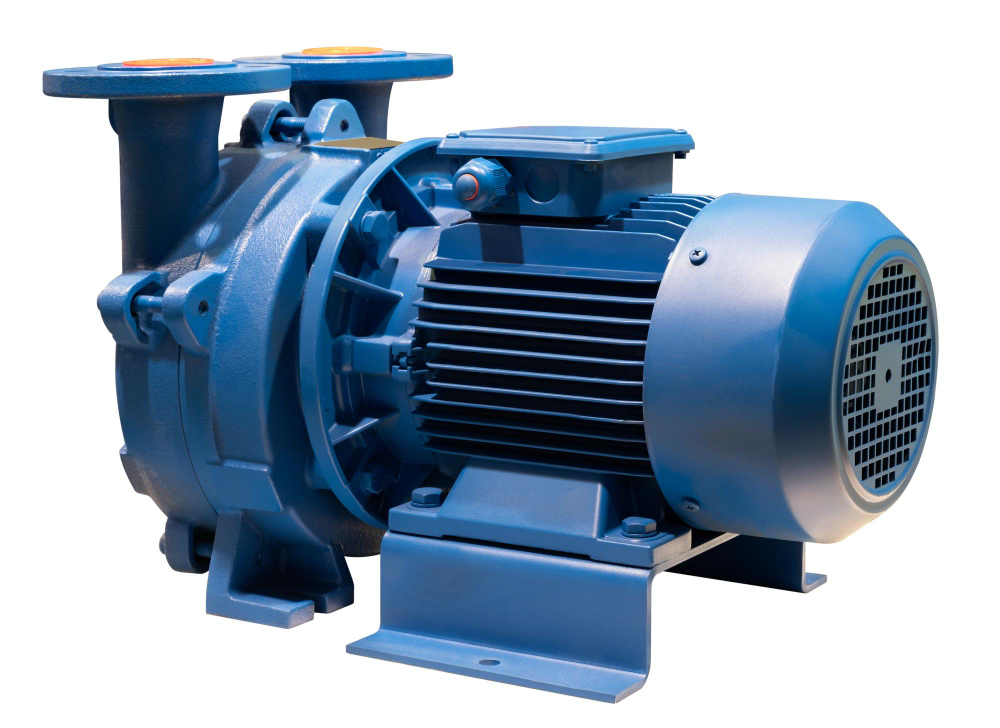

Before we dive into the steps, let’s explore why CH&E diaphragm pumps have gained such a solid reputation in the industry. Diaphragm pumps are known for their versatility and ability to handle a variety of fluids, including aggressive chemicals, slurries, and viscous liquids. These pumps operate by using a flexible diaphragm to move fluids, offering a seal-free design that eliminates the risk of leakage and reduces maintenance needs.

Now, let’s embark on our journey to finding the ideal CH&E diaphragm pump.

Step 1: Define Your Application Requirements

The first and most crucial step is to clearly define your application’s requirements. Understanding the type of fluid you’ll be pumping, the flow rate, pressure, and temperature conditions is essential. Are you dealing with water, chemicals, or highly viscous materials? Are you working in an explosive environment where an air-operated diaphragm pump is necessary?

For example, if you’re handling aggressive chemicals in an industrial setting, a CH&E diaphragm pump made of corrosion-resistant materials would be ideal to ensure safe and efficient operation.

Step 2: Consider Pump Efficiency

Efficiency is paramount when it comes to CH&E pumps. These pumps are designed to minimize energy consumption while delivering reliable performance. Look for diaphragm pumps that meet or exceed industry standards for efficiency. Air-operated diaphragm pumps are particularly beneficial in energy-sensitive applications, as they can operate without electrical power, reducing energy consumption.

Imagine you run a paint manufacturing facility. By choosing an efficient CH&E diaphragm pump, you can ensure consistent flow and reduce energy costs, leading to more sustainable operations.

Step 3: Evaluate Pump Materials and Construction

The materials and construction of CH&E diaphragm pumps play a crucial role in their longevity and performance. Consider factors such as chemical resistance, durability, and compatibility with the fluid being pumped. Depending on your application, you may need pumps made from materials like PTFE (Teflon), stainless steel, or polypropylene to handle corrosive or abrasive fluids.

For example, in food and beverage processing, using a diaphragm pump constructed from food-grade materials ensures compliance with safety standards and guarantees reliable, contamination-free pumping.

Step 4: Assess Maintenance and Serviceability

Maintenance is an aspect often overlooked until a pump faces issues. Diaphragm pumps, particularly those from CH&E, are designed for ease of maintenance, with fewer moving parts and no mechanical seals to replace. Opt for models that allow for easy diaphragm replacement and have readily accessible components to minimize downtime.

If you are managing a wastewater treatment plant, choosing a CH&E diaphragm pump with easy access to wear parts can reduce operational downtime and ensure continuous fluid transfer.

Step 5: Seek Expert Advice and Perform a Comparative Analysis

While you now understand your requirements better, it’s always wise to seek expert advice. Engaging with a trusted supplier or consulting with engineers experienced in diaphragm pumps can provide valuable insights. They can help you perform a comparative analysis of available options, considering factors like initial cost, life-cycle cost, and warranties.

In real-life scenarios, consulting with experts and conducting a comparative analysis is like hiring a professional guide for a challenging project. Their experience can save you from potential pitfalls and ensure a successful outcome.

The Takeaway

In conclusion, finding the perfect CH&E diaphragm pump doesn’t have to be a daunting task. By following these five steps, you can streamline the decision-making process and select the ideal pump for your specific application. Remember to define your requirements, prioritize efficiency, assess construction materials, consider maintenance, and seek expert advice. By doing so, you’ll be well on your way to ensuring reliable and efficient fluid management with CH&E diaphragm pumps.

Recap